We have seen our coffee machines on the net …

We are delighted to know about them…

We are delighted to know about them…

If you are a #coffeelover and have some photos of our products, you can send them to news@ascaso.com

If you are a #coffeelover and have some photos of our products, you can send them to news@ascaso.com

Thank you!

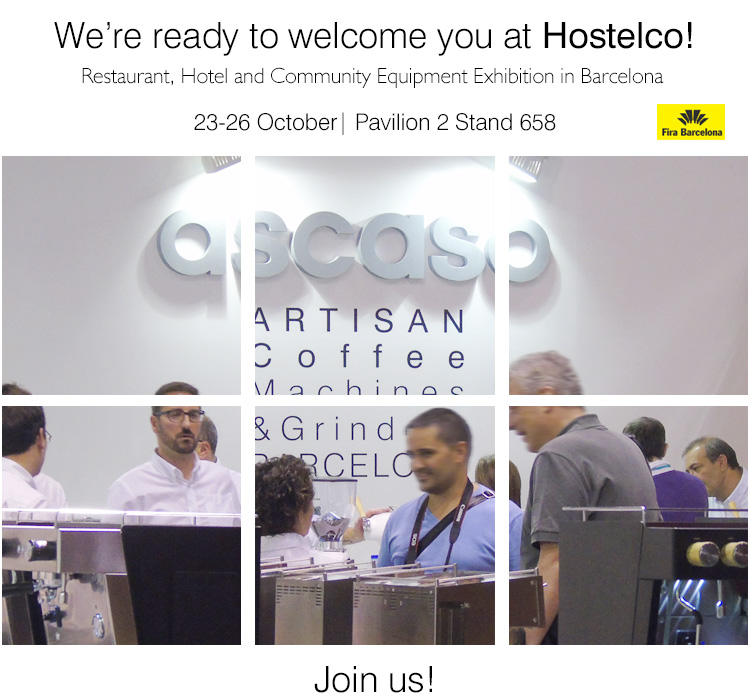

Upcoming Events.

September : We will in Congrès des Torrefacteurs in Nantes ( France)

October : From 23 to 26 October in Hostelco ( Barcelona) with new products and new ideas.

|

P2 , Level 0 , Street F , Stand 658. |

|

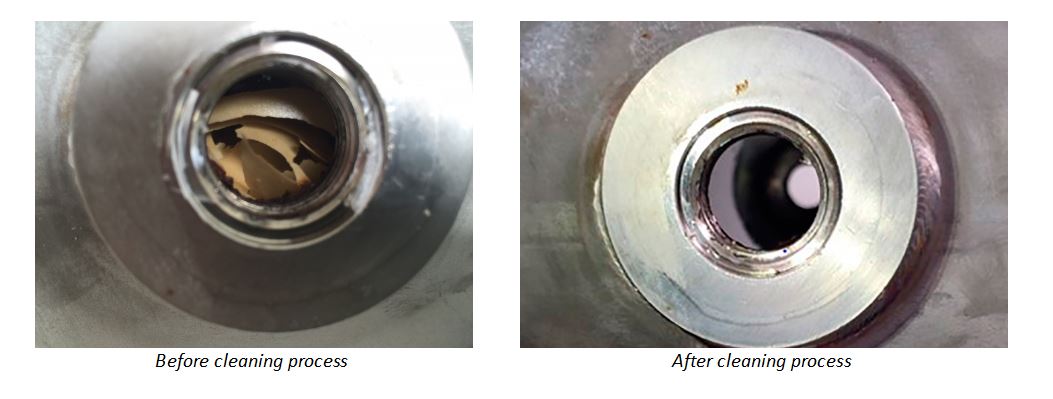

Technology in stainless steel: The anti-limescale boiler.

Limescale is the cause of 80% of repairs to professional coffee machines.

Limescale is the cause of 80% of repairs to professional coffee machines.

There are many systems on the market to reduce the presence of limescale but for a number of reasons they often do not work. This is even more the case in hard water areas.

On the one hand, the traditional materials used for making coffee machines (copper and brass) have a high level of limescale adherence. Its build-up in heat pipes and boiler couplings leads to irregular operation of the machine (unstable temperatures, variable flows, insufficient drying, etc.) and can even block it up, leading to costly repairs.

Stainless steel (AISI 316L): anti-limescale

Our boilers and couplings are made from AISI 316L stainless steel and take four times longer to fur up.

Our boilers and couplings are made from AISI 316L stainless steel and take four times longer to fur up.

Limescale does not adhere to stainless steel but remains in suspension and ends up in the liquid.

Cleaning takes just half an hour: just the heat fittings.

Thanks to this exceptional feature, cleaning coffee and steam boilers is so much quicker and easier than in the case of copper appliances. There is no need to dismantle the machine and the boiler or to use acid solutions. This operation, which can sometimes take hours, is complicated and hazardous and the acid solution damages the copper and welding.

With stainless steel boilers, cleaning becomes a simple operation lasting just over half an hour. Only the heat fittings build up ‘floating’ limescale and simply by running a standard cleaning product through all the machine’s pipes can be thoroughly cleaned.

With stainless steel boilers, cleaning becomes a simple operation lasting just over half an hour. Only the heat fittings build up ‘floating’ limescale and simply by running a standard cleaning product through all the machine’s pipes can be thoroughly cleaned.

The boiler will remain clean throughout its useful life.

For more information on our stainless steel technology, please contact us.

For more information on our stainless steel technology, please contact us.